Full disclosure: this is part confession, part rant and part

technical breakdown of obsolete tech. And it’s probably going to be

long. You were warned…

The Story So Far…

First, some history. When I was growing up, we had a Grundig Majestic (links to which are sketchy and few) console radio/turntable that I sorta unofficially inherited for my room. And I fell in love with this thing. It had the best sound of anything I was hearing, and it sounded distinctly different. And that’s because it used tubes as the active elements.

Fast-forward to about 10 years ago. I thought it would be a fun side

gig to design and produce tube amps for money. So I created my first design, just to get my feet wet, with an EL84 ultra linear output stage, 6922 concertina and a 12AX7

input/bass/treble section. It was a great success for me, and I dressed

that sucker up with LEDs and a bunch of other features. And once that

was done, I started on the next design with an EL34 output section, and I

got some (6) output transformers custom-built by a gentleman from the

Seattle area who was wise in the ways of such things.

Then my partner and I went to the Rocky Mountain Audio Fest. I was really happy with my work thus far, but I needed to immerse myself more in the ways of the competition. But in attending, I came face-to-face with the sort of bald-faced lying that happens in the audiophile gear genre — $100K+ for a pair of speakers. Little sawhorses propping up a power cable a few inches off the floor because, you know, we don’t want to get any floor-induced parasitics into the audio. All justified with lines like, “Achieve the truest representation of what the artist intended.” Are you kidding me? Listen, I’ve been on the other side of this equation before, and you’re giving this imaginary “artist” person way too much credit. And these sawhorses…do you know what happens to your precious line voltage on the other side of that outlet? But oh, the clarity! Right. Miles and miles of unshielded cable and substations, and you think you’ve improved your sound by suspending the power cable 6 inches above your floor for the 4 feet between the wall outlet and your gear? Pardon me for saying, but I think that if you put any stock in that tripe, you probably deserve to pay $4K for RCA patch cables.

But whatever, right? People have to have their hobbies, and I’ve spent tons of dough on mine. It so happens that for this hobby, the exorbitant prices to participate are less about the sound of the gear than the identity it buys the purchaser. That’s fine, and not entirely uncommon. But I’m not going to be the one to tell you stories to extract as much of your money as possible. I just can’t be that guy. Bad businessman Pete, I guess. The quandary brought the project to a halt.

Then some life happened. Kids and all that goes with them, and various other extreme draws on my time and energy. But about five-ish years ago, I decided that I couldn’t let those output transformers I bought sit on the shelf forever. I had to finish the design and build the two EL34 monoblocks I had planned years before. It’s been a long haul, but this past Xmas I was determined to finish these two amps. Why has it taken so long? Lots of reasons, top of the list being the kids. And it doesn’t help that I’ve got the attention span of a gnat. But also, Bluetooth® speakers are just so convenient! And I also started at some point to buy digital music. Phone/tablet/computer + Bluetooth speaker + MP3s = a really easy and portable soundtrack to your life. Does that combination sound as good as a tube amp and a pair of nice B&W speakers? It sure does NOT. But it’s just convenient enough to keep my amps terminally on the back burner. Until this last Xmas.

Now, I have to admit that I didn’t technically meet the challenge. I did not finish both amps. But I did effectively finish one — all the bugs worked out, passing audio and sounding really, really good. The second one should just be turning the crank. Heh. Yeah.

The Design

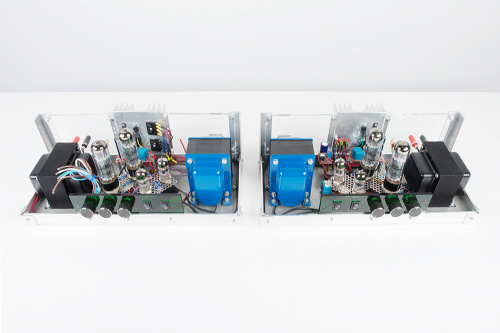

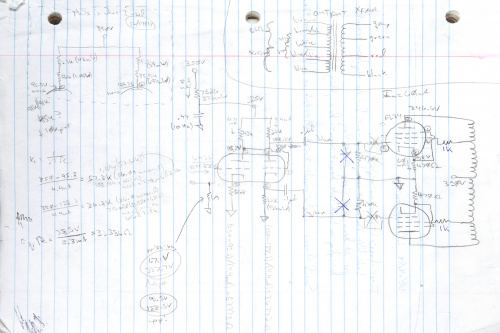

But enough of that. What are we actually looking at? It’s largely the monoblock design I talked about above, and the two of them are book-ended. 12AX7 input/bass/treble section, 6922 concertina and an EL34 ultra-linear output section. The HT supply is regulated 350V, and half of the LT supply is DC-regulated 6.3V. Schematics graciously provided by my notebook. This is all point-to-point wiring, so an electronic form of the schematics doesn’t currently exist. They may be a little sketchy for the casual observer, so lemme know of you’ve got questions.

I’ll start with the LT supply (low voltage, high current for heaters) because it’s the section that’s given me the most grief to get right. First, keeping 60Hz out of the audio is paramount, which is why I went for regulated supplies. But with 6.3VAC RMS (8.9V peak) out of its low voltage winds, the power transformer I chose didn’t give me much headroom to pull that off for the 3.6 amps the tubes were going to need for their heaters. I swear I did all these calculations back in the day that would allow this purchase…but it appeared I had shortcut myself into a corner. To illustrate, 8.9V peak - 2 diode drops (1.2V) - regulator dropout (negotiable, but call it a very generous 1V) - 6.3V output = 0.4V allowable ripple voltage. More than that and the regulator fails to regulate. I’ll spare you the equation, but that takes many tens of thousands of uF to accommodate. And while that’s a possible solution, it’s hardly an elegant one. So after many iterations, I ended up with this circuit.

As it turns out, I can effectively ignore 60Hz noise coming from the EL34 heaters because of the push-pull output topology: since the output transformer translates changes in current and the heaters are impacted in the same way by the same noise (as in common mode), any current fluctuations will be equal and opposing, and 60Hz at the output will not result. So I can basically ignore 3 amps for regulating, but I still have to separate the sections with a Schottky diode so that my filter cap for the 12AX7 and 6922 sections doesn’t go to feeding the EL34s. For those, I use just enough capacitance to get the average voltage into a workable range (4,000uF and about 6.4V). For the remaining 600mA, I use a low dropout regulator (LM1084) good to 5 amps, which I’ve made adjustable with a 10-turn trimpot. And using a mere 10,000uF, I can dial out the last of the ripple giving me about 6.1V. The rectifier that feeds both of these sections is also comprised of Schottky diodes good to 8A continuous and 0.2V forward drop (STPS8L30).

Next is the HT supply, which is regulated 350V at 200mA. I had some experience with this topology from my first design, so this one really didn’t present me with any surprises.

I lifted this from a Morgan Jones book, but I think it’s an LT reference design…somebody’s reference design, anyway. I’ll leave it as an exercise for the reader to suss its operation. There’s still a bunch of amp to get to, and this bit isn’t all that interesting. But yes, that’s an LM317 in the middle.

Now let’s talk about audio. My approach here was a little different from what might be expected, for better or worse. I consider it experimental, but I’m really happy with the results so far. EL34s are relatively high power (from my perspective), but I honestly don’t need all that much power. So I’ve traded gain for bandwidth and eliminated the need for global feedback. Or so I think for now — no promises. But in a lot of places where you might think there should be a cap across a cathode resistor, there won’t be one. And the BW versus gain trade-off is why.

The input section is as follows:

I may have lifted this circuit from the same aforementioned Morgan Jones book, but I think I got it off of the DIYAudio forums. If you’re a tube guy/girl, you may recognize it. I’ve spent enough time looking at the circuit to figure out that bass goes to the top of that box and treble goes to the bottom (by evaluating at arbitrarily high and low frequencies). But I’ve largely just accepted these values without recalculating. I’ve built and tested a few, and performance is good, giving a general gain of about 1.

From there we go to a phase-splitting section in a concertina configuration with a 6922 tube, and on to the EL34 output section.

I’ll keep the description high-level. The first stage of the 6922 sets the bias point for the second stage, which gives us equal and complementary signals on the cathode and the plate of the second stage. Those signals drive the matched pair of EL34s, each of which are set with quiescent plate current of 60mA. I don’t have a bias adjustment installed (maybe later?), so the tubes have to be matched.

Logistics

The layout of the chassis is nothing earth-shaking. Power (left) and audio (right) transformers are on opposite sides and orthogonal so as not to interfere with each other, tubes are in the middle, power supplies are to the back where I have access to a heat sink, and controls are to the front. As I mentioned earlier, the two monoblocks are book-ended, so everything you see here is swapped left-to-right on the unfinished one. The funny-looking thing that’s stood-off from the heat sink is my heater rectifier. I accidentally ordered the wrong package for those Schottky diodes (thought I was getting TO-220, ended up with DPAK), so I had to get clever with my heat dissipation. It works well enough for now, but I really need to get those things on the heat sink proper — probably all four diodes on a single PCB flush-mounted to the heat sink.

The chassis itself is comprised of many pieces of metal bolted together. The difficulty with that is that I’ll need to periodically crank all the screws down to make sure everything is well-grounded. Also, the choice of using the green acrylic for a faceplate necessitates running a ground wire to each of the pot cases; otherwise you get a big “pop” in the output every time you touch one.

All the wiring is point-to-point. I like to keep my high-Z lines as short as I can, so components are mounted on the tube sockets. Morgan Jones would describe these examples as “howlers,” but I’m pretty careful keeping things secure and insulated because high voltage scares the bejesus outta me. If this were for production, I might do it differently.

Testing

If you read through my chicken-scratch schematics, you’ll see some notes and numbers indicating test measurements (DC bias points, really). But primarily, the difficulties I’ve run into are:

I haven’t tested for power output. Well…I was listening to it in my basement the other night, and my wife later accused me of “rocking out down there” with something of a sneer in her voice. I’d call that a successful test.

Changes? Additions?

Besides the things I’ve already mentioned (updated heat sinking for the LT rectifier, bias adjustment for the EL34s)…

References

I’ve mentioned the name Morgan Jones a couple of times. If you’re interested in such esoterica as vacuum tubes, I’d highly recommend checking out his books.

The Story So Far…

First, some history. When I was growing up, we had a Grundig Majestic (links to which are sketchy and few) console radio/turntable that I sorta unofficially inherited for my room. And I fell in love with this thing. It had the best sound of anything I was hearing, and it sounded distinctly different. And that’s because it used tubes as the active elements.

My baby’s seen better days, but she’s all there.

Then my partner and I went to the Rocky Mountain Audio Fest. I was really happy with my work thus far, but I needed to immerse myself more in the ways of the competition. But in attending, I came face-to-face with the sort of bald-faced lying that happens in the audiophile gear genre — $100K+ for a pair of speakers. Little sawhorses propping up a power cable a few inches off the floor because, you know, we don’t want to get any floor-induced parasitics into the audio. All justified with lines like, “Achieve the truest representation of what the artist intended.” Are you kidding me? Listen, I’ve been on the other side of this equation before, and you’re giving this imaginary “artist” person way too much credit. And these sawhorses…do you know what happens to your precious line voltage on the other side of that outlet? But oh, the clarity! Right. Miles and miles of unshielded cable and substations, and you think you’ve improved your sound by suspending the power cable 6 inches above your floor for the 4 feet between the wall outlet and your gear? Pardon me for saying, but I think that if you put any stock in that tripe, you probably deserve to pay $4K for RCA patch cables.

But whatever, right? People have to have their hobbies, and I’ve spent tons of dough on mine. It so happens that for this hobby, the exorbitant prices to participate are less about the sound of the gear than the identity it buys the purchaser. That’s fine, and not entirely uncommon. But I’m not going to be the one to tell you stories to extract as much of your money as possible. I just can’t be that guy. Bad businessman Pete, I guess. The quandary brought the project to a halt.

Then some life happened. Kids and all that goes with them, and various other extreme draws on my time and energy. But about five-ish years ago, I decided that I couldn’t let those output transformers I bought sit on the shelf forever. I had to finish the design and build the two EL34 monoblocks I had planned years before. It’s been a long haul, but this past Xmas I was determined to finish these two amps. Why has it taken so long? Lots of reasons, top of the list being the kids. And it doesn’t help that I’ve got the attention span of a gnat. But also, Bluetooth® speakers are just so convenient! And I also started at some point to buy digital music. Phone/tablet/computer + Bluetooth speaker + MP3s = a really easy and portable soundtrack to your life. Does that combination sound as good as a tube amp and a pair of nice B&W speakers? It sure does NOT. But it’s just convenient enough to keep my amps terminally on the back burner. Until this last Xmas.

Now, I have to admit that I didn’t technically meet the challenge. I did not finish both amps. But I did effectively finish one — all the bugs worked out, passing audio and sounding really, really good. The second one should just be turning the crank. Heh. Yeah.

The Design

But enough of that. What are we actually looking at? It’s largely the monoblock design I talked about above, and the two of them are book-ended. 12AX7 input/bass/treble section, 6922 concertina and an EL34 ultra-linear output section. The HT supply is regulated 350V, and half of the LT supply is DC-regulated 6.3V. Schematics graciously provided by my notebook. This is all point-to-point wiring, so an electronic form of the schematics doesn’t currently exist. They may be a little sketchy for the casual observer, so lemme know of you’ve got questions.

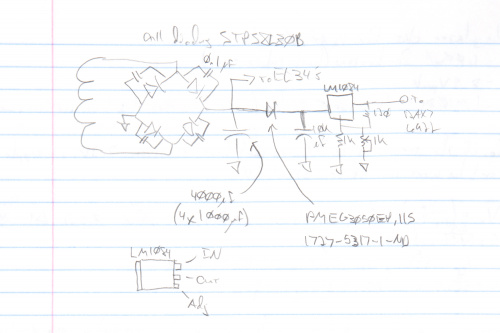

I’ll start with the LT supply (low voltage, high current for heaters) because it’s the section that’s given me the most grief to get right. First, keeping 60Hz out of the audio is paramount, which is why I went for regulated supplies. But with 6.3VAC RMS (8.9V peak) out of its low voltage winds, the power transformer I chose didn’t give me much headroom to pull that off for the 3.6 amps the tubes were going to need for their heaters. I swear I did all these calculations back in the day that would allow this purchase…but it appeared I had shortcut myself into a corner. To illustrate, 8.9V peak - 2 diode drops (1.2V) - regulator dropout (negotiable, but call it a very generous 1V) - 6.3V output = 0.4V allowable ripple voltage. More than that and the regulator fails to regulate. I’ll spare you the equation, but that takes many tens of thousands of uF to accommodate. And while that’s a possible solution, it’s hardly an elegant one. So after many iterations, I ended up with this circuit.

As it turns out, I can effectively ignore 60Hz noise coming from the EL34 heaters because of the push-pull output topology: since the output transformer translates changes in current and the heaters are impacted in the same way by the same noise (as in common mode), any current fluctuations will be equal and opposing, and 60Hz at the output will not result. So I can basically ignore 3 amps for regulating, but I still have to separate the sections with a Schottky diode so that my filter cap for the 12AX7 and 6922 sections doesn’t go to feeding the EL34s. For those, I use just enough capacitance to get the average voltage into a workable range (4,000uF and about 6.4V). For the remaining 600mA, I use a low dropout regulator (LM1084) good to 5 amps, which I’ve made adjustable with a 10-turn trimpot. And using a mere 10,000uF, I can dial out the last of the ripple giving me about 6.1V. The rectifier that feeds both of these sections is also comprised of Schottky diodes good to 8A continuous and 0.2V forward drop (STPS8L30).

Next is the HT supply, which is regulated 350V at 200mA. I had some experience with this topology from my first design, so this one really didn’t present me with any surprises.

I lifted this from a Morgan Jones book, but I think it’s an LT reference design…somebody’s reference design, anyway. I’ll leave it as an exercise for the reader to suss its operation. There’s still a bunch of amp to get to, and this bit isn’t all that interesting. But yes, that’s an LM317 in the middle.

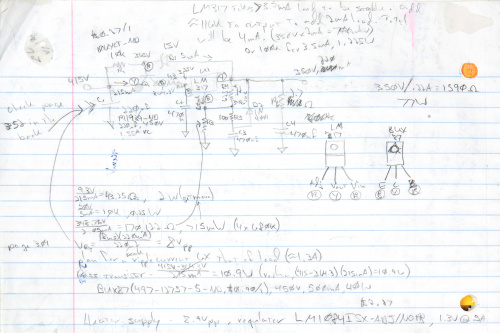

Now let’s talk about audio. My approach here was a little different from what might be expected, for better or worse. I consider it experimental, but I’m really happy with the results so far. EL34s are relatively high power (from my perspective), but I honestly don’t need all that much power. So I’ve traded gain for bandwidth and eliminated the need for global feedback. Or so I think for now — no promises. But in a lot of places where you might think there should be a cap across a cathode resistor, there won’t be one. And the BW versus gain trade-off is why.

The input section is as follows:

I may have lifted this circuit from the same aforementioned Morgan Jones book, but I think I got it off of the DIYAudio forums. If you’re a tube guy/girl, you may recognize it. I’ve spent enough time looking at the circuit to figure out that bass goes to the top of that box and treble goes to the bottom (by evaluating at arbitrarily high and low frequencies). But I’ve largely just accepted these values without recalculating. I’ve built and tested a few, and performance is good, giving a general gain of about 1.

From there we go to a phase-splitting section in a concertina configuration with a 6922 tube, and on to the EL34 output section.

I’ll keep the description high-level. The first stage of the 6922 sets the bias point for the second stage, which gives us equal and complementary signals on the cathode and the plate of the second stage. Those signals drive the matched pair of EL34s, each of which are set with quiescent plate current of 60mA. I don’t have a bias adjustment installed (maybe later?), so the tubes have to be matched.

Logistics

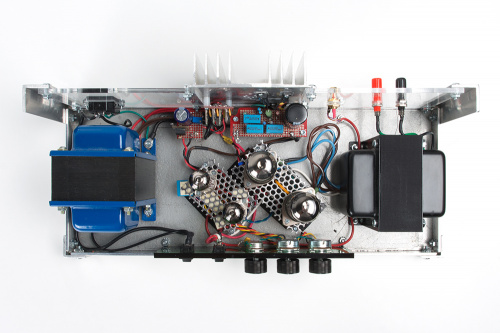

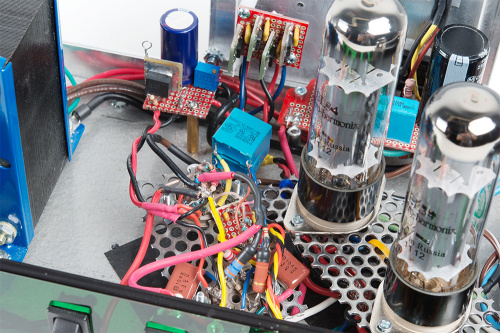

The layout of the chassis is nothing earth-shaking. Power (left) and audio (right) transformers are on opposite sides and orthogonal so as not to interfere with each other, tubes are in the middle, power supplies are to the back where I have access to a heat sink, and controls are to the front. As I mentioned earlier, the two monoblocks are book-ended, so everything you see here is swapped left-to-right on the unfinished one. The funny-looking thing that’s stood-off from the heat sink is my heater rectifier. I accidentally ordered the wrong package for those Schottky diodes (thought I was getting TO-220, ended up with DPAK), so I had to get clever with my heat dissipation. It works well enough for now, but I really need to get those things on the heat sink proper — probably all four diodes on a single PCB flush-mounted to the heat sink.

The chassis itself is comprised of many pieces of metal bolted together. The difficulty with that is that I’ll need to periodically crank all the screws down to make sure everything is well-grounded. Also, the choice of using the green acrylic for a faceplate necessitates running a ground wire to each of the pot cases; otherwise you get a big “pop” in the output every time you touch one.

All the wiring is point-to-point. I like to keep my high-Z lines as short as I can, so components are mounted on the tube sockets. Morgan Jones would describe these examples as “howlers,” but I’m pretty careful keeping things secure and insulated because high voltage scares the bejesus outta me. If this were for production, I might do it differently.

Testing

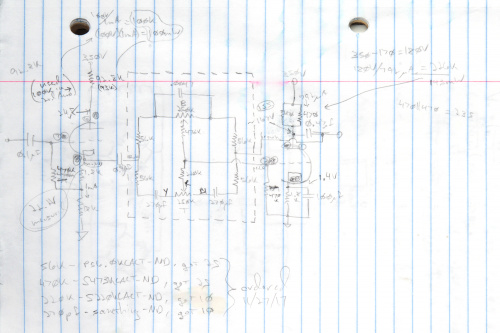

If you read through my chicken-scratch schematics, you’ll see some notes and numbers indicating test measurements (DC bias points, really). But primarily, the difficulties I’ve run into are:

- LT supply. How many times did I have to go around that block before I was happy? I lost count.

- Missing grid resistor on the first stage of the 6922 messed up my bias points for both stages.

- Plate current for the EL34s came in a little lower than expected at 55mA. It brings the bias point a little closer to a less active region, but it doesn’t seem to be a problem for the sound. I’ve also got 400 ohm resistors I can swap out for the 470s that are there now, and I’ve got plenty of headroom from my HT supply. But I won’t throw the power away if I don’t have to, in spite of all that junk I said about trading gain for BW.

- 60Hz everywhere. Everything’s got to be well-grounded, and all references must be shared. Don’t try to get clever with this; it will only make you cry.

I haven’t tested for power output. Well…I was listening to it in my basement the other night, and my wife later accused me of “rocking out down there” with something of a sneer in her voice. I’d call that a successful test.

Changes? Additions?

Besides the things I’ve already mentioned (updated heat sinking for the LT rectifier, bias adjustment for the EL34s)…

- LEDs! Not addressable, flashy junk; that’s just gauche. But on my first design I had red LEDs illuminating the underside of the tubes to indicate low voltage presence. Then blue LEDs would illuminate the tubes when you had the HT turned on. I’ll probably do something similar here.

- Bias monitoring at all stages. Also a thing I had set up on the last one, and it always kept me informed as to what the circuit conditions were, and would switch off the HT if something were dramatically out of whack.

- Relay connection of the speakers to the output transformer. Again, had it in the first design; haven’t implemented here. There’s a big “pop” in the speaker when the HT gets turned on that I should make go away. Switching on the speakers after that power-up would fix it.

References

I’ve mentioned the name Morgan Jones a couple of times. If you’re interested in such esoterica as vacuum tubes, I’d highly recommend checking out his books.

No comments:

Post a Comment