A scramjet engine is a supersonic-combustion engine that ditches the compressor and turbine of a typical jet engine and can attain speeds greater than Mach 5!

A

few months ago, India’s DRDO (Defense Research and Development

Organization) made the news for successfully conducting the maiden

flight test of its unmanned scramjet demonstration aircraft for

hypersonic speed flight. Yes, that’s a mouthful. The demonstration

aircraft was officially called the ‘Hypersonic Technology Demonstrator

Vehicle (HSTDV)’. The aircraft was designed to achieve speeds greater

than Mach 6. To put that into perspective, a passenger aircraft travels

at a speed significantly below Mach 1.

Speeds

of Mach 6 or higher are achieved by using scramjet technology. Scramjet

technology is extremely difficult to develop and, before India, only

three other nations (USA, Russia, and China) have been successful in

developing such a technology.

Vehicles

powered by scramjet engines have been proposed to attain speeds of Mach

12 and higher. (Photo Credit : Marc Ward/ Shutterstock)

What are jet engines?

Before

we take a closer look at scramjet engines, let’s touch upon jet engines

in general. Jet engines are combustion engines that generate thrust (or

movement) through jet propulsion. These engines find application in

high-speed situations, such as jet airplanes, fighter jets, missiles and

drones. Jet engines are also modified for use in high-speed cars and

power plants. A basic jet engine works on the same principle as a

traditional gas turbine.

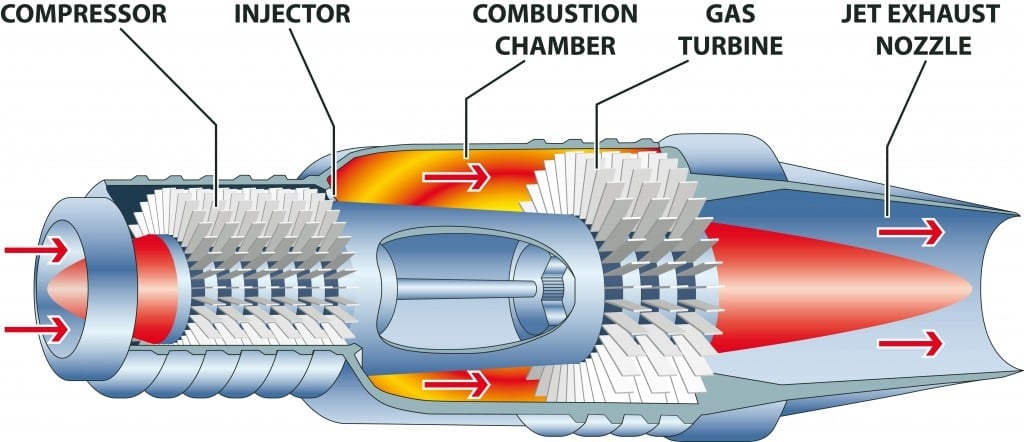

A

basic jet engine consists of a fan, a compressor, a combustion chamber,

and a turbine. (Photo Credit : Stanislav-Z/ Shutterstock)

A

jet engine consists of a compressor at the front followed by a

combustion chamber and a turbine. The compressor and turbine are mounted

on the same shaft. A fan at the front of the compressor sucks in air

from the atmosphere.

The

compressor, composed of multiple blades rotating at high speeds on a

shaft, then compresses the incoming air. The pressure and temperature of

the air increases and the speed drops as a result of this compression.

Whereas in the combustion chamber, fuel is sprayed on the compressed air

and a spark from the spark plug ignites the mixture.

The

mixture then expands spontaneously, creating a jet. The reaction force

generated from the jet trying to blast out of the nozzle provides the

necessary thrust to move the plane/vehicle forward. The amount of thrust

that is generated depends on the speed of the exiting jet in comparison

to the speed of the inlet air. The greater the speed of the exiting

jet, the greater the amount of thrust produced.

Before exiting the engine, the jet

passes through the turbine blades. The movement imparted by the exiting

jet on the turbine blades is transferred to the compressor by a shaft.

Shortcomings of the traditional jet engine

A

major drawback of the traditional jet engine is the number of moving

parts it incorporates. The list includes the multi-stage compressor and

turbine rotors, as well as other mechanical components, such as spark

plugs, cooling systems, afterburners, a fuel control unit, prime mover,

etc. These components add a lot of weight to the overall engine, making

the entire vehicle heavier. The engineering complexity and the number of

elements that could fail and lead to an engine failure or shutdown also

increase dramatically with so many parts.

Moreover,

the dream of traveling from one place to another on Earth at supersonic

speeds isn’t attainable with a regular jet engine. Most jet engines can

only accomplish subsonic speeds, i.e, speeds below Mach 1, although a

very small number can fly at speeds of around Mach 3.

This is where ramjets and scramjet engines come into play.

What are ramjet and scramjet engines?

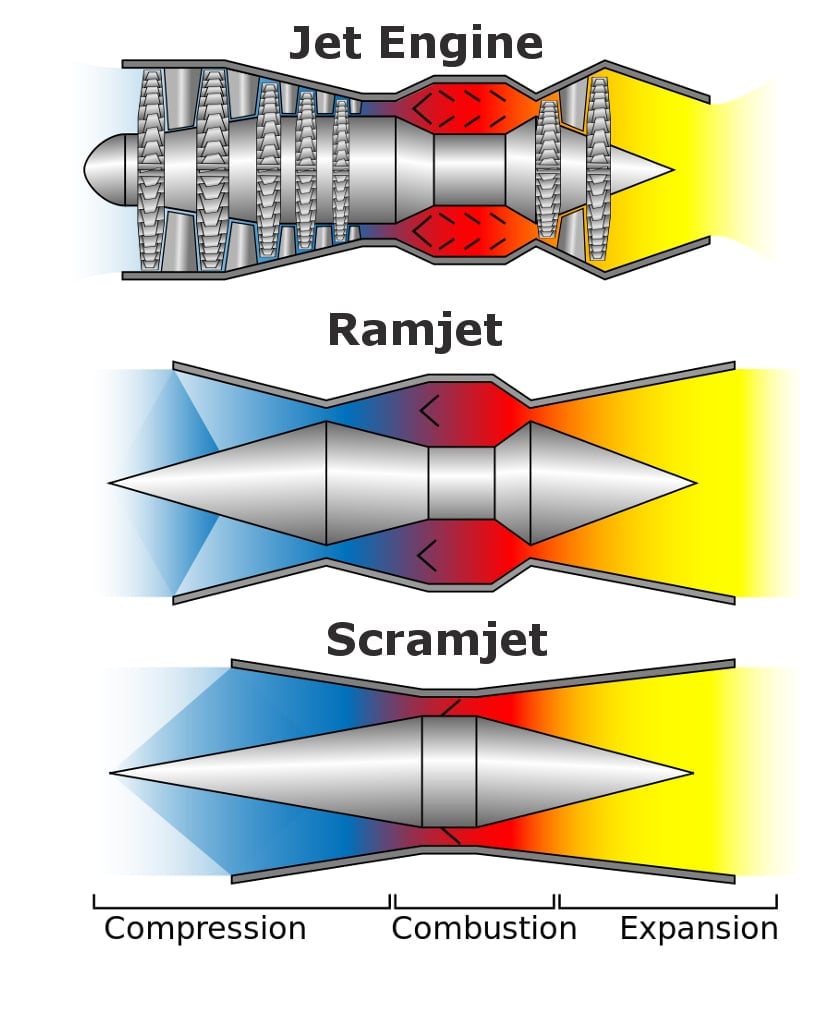

Ramjet

and scramjet engines are jet engine variants that ditch the rotary

compressor and turbine from a regular jet engine. The two models rely on

the natural ramming of air to produce thrust. The basic operating

principle in ramjets and scramjets involves converting the significant

kinetic energy of the incoming hypersonic (speed greater than Mach 5) or

supersonic air into pressure energy.

Air flowing at hypersonic speeds has

very high dynamic pressure. Dynamic pressure is also called velocity

pressure and is formally defined as the kinetic energy per unit of

volume. You might remember it as a term in Bernoulli’s equation (P + ½ ρ

v2 +ρ g h = constant, where the term ‘½ ρ v2‘ is dynamic pressure).

However,

the dynamic pressure of air flowing at subsonic speeds is insufficient

to produce any usable thrust. Furthermore, when an aircraft is at a

standstill, the dynamic pressure of the air surrounding it is even lower

and cannot be used to produce thrust.

Thus, ramjets and scramjets require

assistance for their initial take-off until the plane attains a specific

speed. Both types operate efficiently only when the surrounding air is

flowing at no less than supersonic speeds, starting from Mach 3.

Ramjets

and scramjets do not make use of a rotary compressor and turbine to

generate thrust, instead relying on the natural ramming of air. (Photo

Credit : GreyTrafalgar/Wikimedia Commons)

Now,

regarding the construction of the two jet engines, the compressor of

the regular jet engine at the front is replaced by a diffuser, while the

other end of the engine is occupied by a propelling

(convergent-divergent) nozzle.

Diffusers

are devices used to reduce the velocity of a fluid (incoming air, in

our case) and increase its pressure and temperature. Nozzles, on the

other hand, are utilized to decrease the pressure and increase the

velocity of a fluid (exhaust jet). Since there is no compressor in

ramjet and scramjet engines, the need for a turbine is also eliminated.

When

air moving at hypersonic speeds is forced to pass through the diffuser,

its dynamic pressure is converted into static pressure. The speed of

the airflow decreases, while the pressure and temperature increase. This

increased temperature and pressure aid in the combustion of the

mixture.

The

rest of the working procedure remains the same as in a regular jet

engine. Inside the combustion chamber, the air is mixed with fuel and

spark plugs help ignite the mixture, while the propelling nozzle

accelerates the exhaust stream to generate thrust.

Ramjets vs Scramjets

In

a ramjet, the incoming air is slowed down to below subsonic levels by

the diffuser. It makes use of oblique shock waves to slow the flow down,

followed by a final normal shock wave to bring it below subsonic

speeds. Since the amount of thrust generated depends on the speed of the

exhaust jet, in ramjets, similar to jet engines, the amount of

generated thrust is limited by the subsonic flow of air in the

combustion chamber.

To increase

thrust production, the incoming air must not be slowed down below

subsonic speeds; scramjet engines do just that. Scramjet engines are

nothing but an upgrade to ramjet engines; in fact, scramjet stands for

‘supersonic combustion ramjet engines’.

In scramjets, the incoming airflow is

not slowed down to subsonic levels and maintains supersonic speeds. This

is accomplished by a more gradually diverging diffuser. The combustion

chamber in scramjets is also modified to operate at supersonic speeds,

while the combustion chamber in ramjets only operates at subsonic

speeds.

The propelling nozzle is also

modified to accelerate the exhaust jet to higher Mach numbers. Thus,

the thrust generated by scramjets is more than that of ramjets.

Scramjets, therefore, can fly at greater speeds than ramjets.

Scramjets are also important as they bridge the gap between highly efficient jet engines and high-speed rocket engines.

Scramjets

carry fuel and use the ingested atmospheric oxygen as the oxidizer,

whereas rockets carry both fuel and an oxidizing agent on board. As

scramjets don’t carry an oxidizing agent, they are restricted to

atmospheric flights and can’t be used for space travel… yet.

Conclusion

The use of scramjet technology might let us fly at speeds of more than 10 times

the speed of sound, but it’s still very much a work in progress. As

already mentioned, only 4 nations have been successful in developing

scramjet technology. The very first scramjet engine-powered vehicle took

flight in November of 1991 and was developed by Russia. It has been

approximately 27 years since the first demonstration of scramjet

technology, but it continues to elude us on a large scale.

The

primary problem is the need for an additional launching vehicle to

initiate the flight, as scramjets only produce useful thrust at speeds

of Mach 5 or higher. The amount of heat generated by air friction and

shock waves is another concern. A poor thrust-to-weight ratio limits

acceleration, and the plane also needs to be considerably large to carry

a certain payload. To top it all off, scramjet technology is extremely

expensive to manufacture and test. Most tests end with the complete

annihilation of the test vehicle.

So,

while scramjet technology might seem exciting and useful, it’s

something we won’t likely be seeing for at least another 10-15 years.

No comments:

Post a Comment