Generally, we use certain equipment to generate Electricity. Among them, a boiler plays a key role. For the proper function of the boiler and in order to avoid corrosion inside the boiler we use the deaerator. In the deaerator, the contaminations which are present inside the feed water will be removed. In this article, we will discuss what is a deaerator, working principle, different types of deaerator, its advantages, disadvantages, and applications.

What is the Function of Deaerator

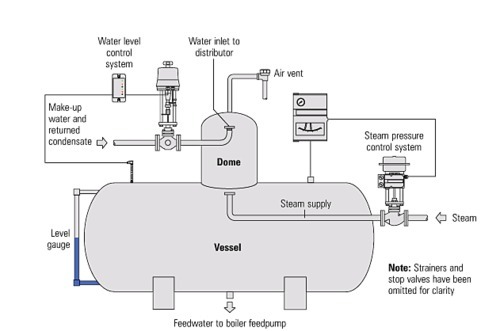

It is an appliance used for the removal of carbon dioxide, oxygen, and other gases. These gases are available in the feed water fed to the boiler. To avoid the corrosion due to these gases in the boiler deaerator is used. The removal of these dissolved gases increases the efficiency and life expectancy of the boiler. The feed water to the boiler is shown in the figure below.

Deaerator

Dearator Working Principle

Deaerator system works according to the principle of two laws. They are

- Henry’s Law

- Inverse solubility Law

Henry’s Law

In conformity to Henry, the pressure available inside the equipment is directly proportional to the solubility of gases. Whenever the pressure present inside is decreased such that the solubility of gases also gets reduced. Hence, the pressure is reduced by the introduction of steam inside the deaerator.

Inverse Solubility Law

In conformity to Inverse solubility Law, the temperature inside the equipment is inversely proportional to the solubility of gases. Whenever the temperature is increased such that the number of dissolved gases inside will be reduced. Thus, the temperature is increased by the introduction of steam inside the deaerator.

Therefore, this is the basic principle of how does a deaerator system work by removing the dissolved gases from the feedwater before supplying to the boiler. They are removed either by decreasing pressure or by increasing temperature but both will be practiced by the introduction of steam.

Deaerator Design & Components

- Pressure valve

- Water level Indicator

- Makeup water inlet

- Air vent

- The pressure value is used to observe the pressure inside the vessel. As the deaerator uses low pressure to decrease the dissolved gases there is a need to monitor the pressure inside.

- The water level indicator is used to know the level of water inside the vessel. If the water is at the bottom level the boiler will run dry and if the water reaches its maximum level there is a chance of overflow. To avoid this, the water level indicator plays a key role.

- The water that is supplied into the vessel to remove the unwanted particles present in it to avoid contamination.

- The dissolved gases in the feed water after removal by the deaeration process are escaped out through the Air vent.

Types of Deaerator

There are three types of deaerator. They are

- Spray Type

- Tray Type, and

- Vacuum Type

Spray Type

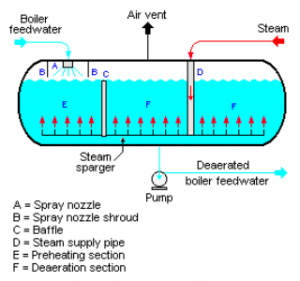

Spray Type deaerator is a cylindrical vessel used for the removal of dissolved gases from the feed water. Basically, the removal of dissolved gases is done by either decreasing the pressure or increasing the temperature inside the deaerator. The feed water fed into the deaerator will pass on through the vented section where the water will experience high steam which allows the feed water to remove dissolved gases. Spray Type deaerator is shown in the figure below.

Spray type Deaerator

The spray type deaerator consists of a spray nozzle, baffle, preheating section, and deaeration section. First of all, the feed water introduced into the deaerator is flown through the spray nozzle inside the vessel. There is a steam supply connected to the vessel which is used to heat the feed water. Then, the water exposed to steam is sent to the preheating section.

In the preheating section, the water is heated by steam until the temperature of the water reaches its saturation point. At this high temperature, the feed water containing dissolved gases will be eliminated. The high-temperature water converted to steam is sent to the deaeration section. In the deaeration section, steam and water droplets will be separated.

The separated dissolved gases are escaped out through the Air vent. And the water droplets free from gases are collected at the bottom of the vessel. The deaerator boiler feed water is fed to the boiler by using a pump. This water is used as the feed water to the boiler which helps in avoiding the corrosion.

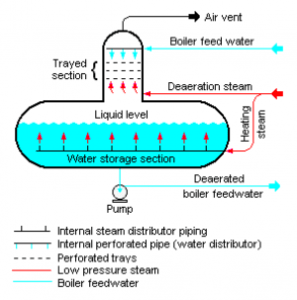

Tray Type

Tray type deaerator is a vertical dome place on the horizontal section of the vessel. The basic difference between a tray-type and spray type is in Tray type both a spray nozzle and trays are used. By using both spray and tray mixing up of air and water is more (heat exchange takes place more properly). By this, the dissolved gases present in the feed water will be eliminated more precisely. Therefore, the efficiency of the boiler can be improved more. The tray Type Deaerator is shown in the figure below.

Tray type deaerator

The boiler feed water fed to the tray type deaerator is sprayed onto the trays using the perforated nozzles. The internal steam distributing pipe supplies the low-pressure steam into the vessel. The water sprayed on to the trays mixes up with air and water at high temperatures. At this temperature, unwanted gases will be eliminated. The water free from the dissolved gases is collected in the vessel at the bottom. This water is fed to the boiler from the deaerated section via a pump.

Vacuum Type

The operation of this type is the same as that of a tray-type but a vacuum pump is used at the air vent. This is used to minimize the vent loses. By minimizing vent loses the efficiency of the boiler can be increased. The vacuum type is shown in the figure below.

Vacuum type

Advantages

- It increases efficiency, life expectancy.

- Reduces operating costs.

- Improves the steam quality.

Disadvantages

- There will be vent loses.

- High maintenance.

- It requires more space.

Applications

- It is used in the chemical process industry and power plants.

- Used in plants where there is no standby capacity.

- Used in plants where there are critical loads.

- It is used in Petroleum Refineries.

Thus, in this article, we had an overview of a deaerator. Basically, it is an appliance used to remove excess oxygen, carbon dioxide and other gases that are present inside the feed water supplied to the boiler. Apart from this, we had also learned how does a deaerator system work, different types, advantages, disadvantages, and applications. Here is a question for the readers, what is deaerator pegging? and What is deaerator water?

No comments:

Post a Comment