Graphene has been considered a

"material of the future" for decades, seemingly always a few years away

from its heyday. Continuing research efforts across several industries,

however, continue to yield promising results, including innovations such

as graphene biosensors, UAVs with graphene "skin", and nanoscale

filters.

We’ve been hearing about graphene for years and how its

use could mark a true revolution in how many things, including

electronic devices, are designed and built. Tapping into graphene's potential, however, has proven complicated. It is extremely difficult to manufacture and so is not commonly found as a construction material. Despite these difficulties, active research into graphene continues at scale.

Here's a quick refresher on why graphene is so sought after and a look at where it's finding applications so far.

What Is Graphene?

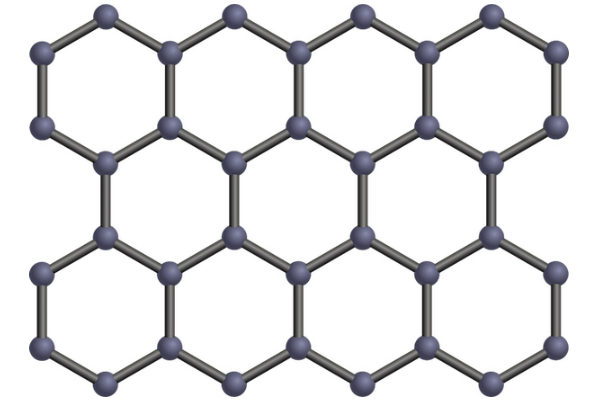

Graphene is a crystalline form (or allotrope) of pure carbon, like coal, charcoal, or graphite. Though the concept of graphene was theorized by scientists for years, it was fully isolated and characterized in 2004 by Andre Geim and Konstantin Novoselov at the University of Manchester. The pair won the Nobel Prize in Physics in 2010 in recognition of their work.Due to its unique inter-atomic structure, graphene is over 100 times stronger than steel—and yet it is flexible. Graphene forms sheets of hexagonally arranged carbon atoms, connected by single and double bonds.

The basic structure of graphene

Graphene is nearly completely flat—the third dimension is only one carbon atom thick—prompting some to call graphene a "2D material".

More importantly (at least, for biosensor development), it is an even better conductor of electricity than carbon.

Biology Meets Physics: Graphene Biosensors

Small-scale applications of graphene are, in some ways, slowly but surely becoming practical. Using methods of 3D printing, graphene can be deposited on surfaces to build transistors. Such transistors are being used as the basis of a new breed of biosensors.Using Graphene Transistors to Create Biosensors

The reason graphene is such a powerfully effective conductor is that it has a zero band gap, which means it takes negligible energy to move an electron out of its orbit around one carbon atom into the orbit of an adjacent carbon atom. It is that uninhibited electron flow that is the definition of a conductor.In order to create a transistor, however, what is needed is a semiconductor, something that sometimes conducts electricity and at other times does not. In order for graphene to function as a semiconductor, therefore, a band gap must be temporarily created, changing graphene from a conductor to a non-conductor. If the application of an outside stimulus can be made to create that bandgap, we then have a transistor.

A biosensor is a device that records an electrical response proportional to the concentration of the biological marker, such as an antibody or an antigen, that it is designed to detect. In a simpler case, if the concentration of the biological entity reaches a detectable level, the biosensor simply turns on, like a switch. A functioning biosensor is formed if the presence of the biological entity can be manipulated to affect the bandgap of our graphene transistor.

Ongoing Research

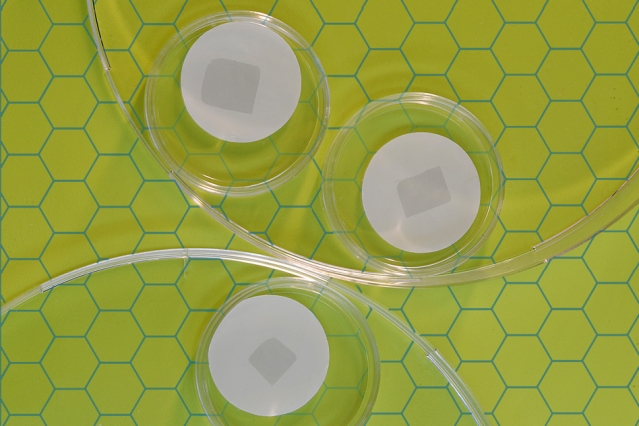

Archer Exploration of Wayville, Australia—in conjunction with the University of Adelaide ARC Graphene Hub—has entered into an agreement with an as yet unnamed German Biotech. The Australians will provide materials such as graphene ink and already extant printed graphene electrodes. The German entity will provide the antigens that will react with the markers that are to be detected by the sensors.The figure below represents graphene electrodes that were developed from graphene-based inks. They represent a collaboration between Archer Exploration and ARC Graphene Hub.

Image used courtesy of Archer

According to a press release provided by Archer, the purpose of this globe-spanning partnership is “to contribute towards fabricating a proof-of-concept biosensor, comprising printable components capable of detecting disease state markers, such as antibodies or antigens.”

It can be expected that this collaboration, in addition to producing biosensors, will advance the state of the art not only of graphene inks, but the overall scalability and practicality of graphene-based technology as a whole. So maybe we’ll see those ultra-light building materials, ultra-fast quantum transistors, and vehicle batteries that charge in minutes rather than hours sooner than we think.

Fabricating Dialysis Membranes Using Graphene Sheets

Even defects in sheets of graphene are proving useful. MIT has announced that purposeful nano-sized pores in graphene membranes the size of postage stamps allow the material to act as a kind of molecule-splitting filter.

MIT's postage stamp-sized sheets of graphene. Photo courtesy of Felice Frankel via MIT News.

A single-atom-thick filter with nanoscopic pores may allow, for example, advances in biochemical dialysis wherein the filter could remove specific molecules from solutions. By affecting the temperature of graphene sheet manufacturing, it becomes possible to control the size of these pores and filter for specific-sized molecules. This, combined with MIT's unique method of etching the pores with oxygen plasma, makes fabricating these filters much more manageable for scalable manufacturing.

You can read more about this topic in the journal Advanced Materials.

Graphene in Aerospace

Where smaller-scale applications may utilize pure graphene, large-scale applications become possible when graphene is used in a composite.Due to its strength and flexibility, graphene composites have been consistently identified as a promising material to be used in aerospace applications. Of course, the relationship between graphene, the aerospace industry, and the press has also weighed in on its popularity. In March of 2017, Sir Richard Branson of Virgin Atlantic claimed that graphene was a "breakthrough" technology and that it would transform the airline industry in 10 years, largely through lighter aircraft utilizing graphene composites that would require less fuel to fly.

One year on from that statement, there have been precious few advancements to confirm or refute Branson's claim. Over the past several years, however, graphene has been implemented in various experimental applications.

In July, engineers from the University of Central Lancashire in the UK, along with industry partners, premiered Juno, a small, lightweight UAV with a graphene "skin"—a first of its kind.

The UCLan team and Juno. Image used courtesy of the University of Central Lancashire

UCLan also sent graphene into near space in December of 2017 via high altitude balloons:

Commercially-available products that incorporate graphene are growing in number. Lightweight wheelchairs, watches, bicycle frames, batteries, and even textiles that use graphene composites have been entering the commercial market. Given that a market intelligence report released today by BIS Research forecasts that the "global graphene-enhanced composites" market will reach $348 billion by 2023, this trend is unlikely to slow down.

In the meantime, research abounds and hopes remain high for how graphene could change industries around the world. As it turns out, the "revolution" of graphene may be happening over time while we wait for it to arrive.

No comments:

Post a Comment