In 1880, Jacques and Pierre Curie discovered an unusual

characteristic of certain crystalline minerals: when subjected to a

mechanical force, the crystals became electrically polarized. Tension

and compression generated voltages of opposite polarity, and in

proportion to the applied force. Subsequently, the converse of this

relationship was confirmed: if one of these voltage-generating crystals

was exposed to an electric field it lengthened or shortened according to

the polarity of the field, and in proportion to the strength of the

field. These behaviors were labeled the piezoelectric effect and the

inverse piezoelectric effect, respectively, from the Greek word piezein,

meaning to press or squeeze.

Although the magnitudes of piezoelectric voltages, movements, or forces are small, and often require amplification (a typical disc of piezoelectric ceramic will increase or decrease in thickness by only a small fraction of a millimeter, for example) piezoelectric materials have been adapted to an impressive range of applications. The piezoelectric effect is used in sensing applications, such as in force or displacement sensors. The inverse piezoelectric effect is used in actuation applications, such as in motors and devices that precisely control positioning, and in generating sonic and ultrasonic signals. In the 20th century metal oxide-based piezoelectric ceramics and other man-made materials enabled designers to employ the piezoelectric effect and the inverse piezoelectric effect in many new applications. These materials generally are physically strong and chemically inert, and they are relatively inexpensive to manufacture. The composition, shape, and dimensions of a piezo ceramic element can be tailored to meet the requirements of a specific purpose. Ceramics manufactured from formulations of lead zirconate / lead titanate exhibit greater sensitivity and higher operating temperatures, relative to ceramics of other compositions, and "PZT" materials currently are the most widely used piezoelectric ceramics.

Although the magnitudes of piezoelectric voltages, movements, or forces are small, and often require amplification (a typical disc of piezoelectric ceramic will increase or decrease in thickness by only a small fraction of a millimeter, for example) piezoelectric materials have been adapted to an impressive range of applications. The piezoelectric effect is used in sensing applications, such as in force or displacement sensors. The inverse piezoelectric effect is used in actuation applications, such as in motors and devices that precisely control positioning, and in generating sonic and ultrasonic signals. In the 20th century metal oxide-based piezoelectric ceramics and other man-made materials enabled designers to employ the piezoelectric effect and the inverse piezoelectric effect in many new applications. These materials generally are physically strong and chemically inert, and they are relatively inexpensive to manufacture. The composition, shape, and dimensions of a piezo ceramic element can be tailored to meet the requirements of a specific purpose. Ceramics manufactured from formulations of lead zirconate / lead titanate exhibit greater sensitivity and higher operating temperatures, relative to ceramics of other compositions, and "PZT" materials currently are the most widely used piezoelectric ceramics.

How are piezo ceramics made?

A traditional piezoelectric ceramic is a mass of perovskite ceramic crystals, each consisting of a small, tetravalent metal ion, usually titanium or zirconium, in a lattice of larger, divalent metal ions, usually lead or barium, and O2- ions (Figure 1.1). Under conditions that confer tetragonal or rhombohedral symmetry on the crystals, each crystal has a dipole moment (Figure 1.1b).To prepare a piezoelectric ceramic, fine PZT powders of the component metal oxides are mixed in specific proportions, then heated to form a uniform powder. The piezo powder is mixed with an organic binder and is formed into structural elements having the desired shape (discs, rods, plates, etc.). The elements are fired according to a specific time and temperature program, during which the piezo powder particles sinter and the material attains a dense crystalline structure. The elements are cooled, then shaped or trimmed to specifications, and electrodes are applied to the appropriate surfaces.

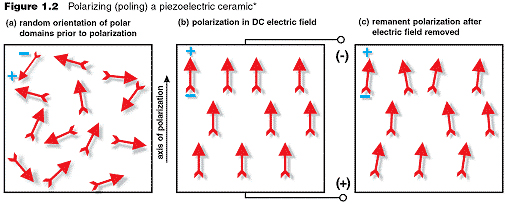

Above a critical temperature, the Curie point, each perovskite crystal in the fired ceramic element exhibits a simple cubic symmetry with no dipole moment (Figure 1.1a). At temperatures below the Curie point, however, each crystal has tetragonal or rhombohedral symmetry and a dipole moment (Figure 1.1b). Adjoining dipoles form regions of local alignment called domains. The alignment gives a net dipole moment to the domain, and thus a net polarization. The direction of polarization among neighboring domains is random, however, so the ceramic element has no overall polarization (Figure 1.2a).

The domains in a piezo ceramic element are aligned by exposing the element to a strong, direct current electric field, usually at a temperature slightly below the Curie point (Figure 1.2b). Through this polarizing (poling) treatment, domains most nearly aligned with the electric field expand at the expense of domains that are not aligned with the field, and the element lengthens in the direction of the field. When the electric field is removed most of the dipoles are locked into a configuration of near alignment (Figure 1.2c). The element now has a permanent polarization, the remanent polarization, and is permanently elongated.

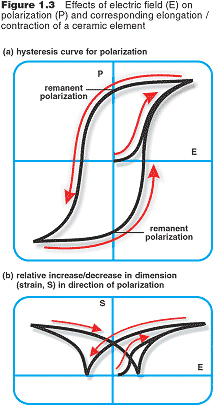

Analogous to corresponding characteristics of ferromagnetic materials, a poled ferroelectric material exhibits hysteresis. Figure 1.3 shows a typical hysteresis curve created by applying an electric field to a piezoelectric ceramic element until maximum polarization, Ps , is attained, reducing the field to zero to determine the remanent polarization, Pr , reversing the field to attain a negative maximum polarization and negative remanent polarization, and re-reversing the field to restore the positive remanent polarization. The tracing below the hysteresis curve plots the relative change in the dimension of the ceramic element along the direction of polarization, corresponding to the change in the electric field. The relative increase / decrease in the dimension parallel to the direction of the electric field is accompanied by a corresponding, but approximately 50% smaller, relative decrease / increase in the dimension perpendicular to the electric field. Figure 1.3. Effects of Electric Field (E) on Polarization (P) and Corresponding Elongation / Contraction of a Ceramic Element

What can piezoelectric ceramics do?

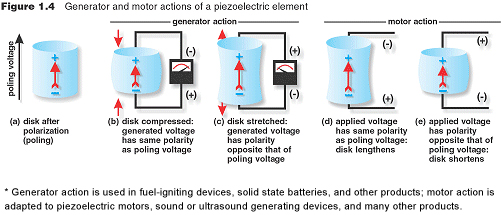

Mechanical compression or tension on a poled piezoelectric ceramic element changes the dipole moment, creating a voltage. Compression along the direction of polarization, or tension perpendicular to the direction of polarization, generates voltage of the same polarity as the poling voltage (Figure 1.4b). Tension along the direction of polarization, or compression perpendicular to the direction of polarization, generates a voltage with polarity opposite that of the poling voltage (Figure 1.4c). These actions are generator actions -- the ceramic element converts the mechanical energy of compression or tension into electrical energy. This behavior is used in fuel-igniting devices, solid state batteries, force-sensing devices, and other products. Values for compressive stress and the voltage (or field strength) generated by applying stress to a piezoelectric ceramic element are linearly proportional up to a material-specific stress. The same is true for applied voltage and generated strain.If a voltage of the same polarity as the poling voltage is applied to a ceramic element, in the direction of the poling voltage, the element will lengthen and its diameter will become smaller (Figure 1.4d). If a voltage of polarity opposite that of the poling voltage is applied, the element will become shorter and broader (Figure 1.4e). If an alternating voltage is applied, the element will lengthen and shorten cyclically, at the frequency of the applied voltage. This is motor action -- electrical energy is converted into mechanical energy. The principle is adapted to piezoelectric motors, sound or ultrasound generating devices, and many other products.

No comments:

Post a Comment