Introduction

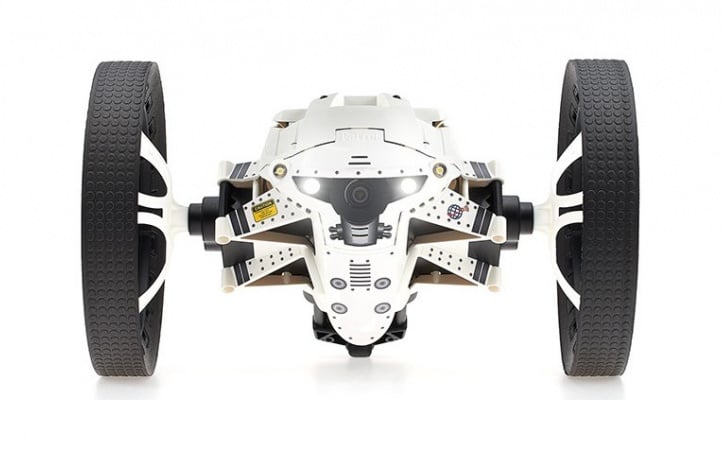

The Jumping Sumo Robot. Image source: Parrot

Toys are getting more and more complicated! In this Teardown Tuesday, we are going to take a look at the insides of the Parrot Jumping Sumo Robot. This robotic toy is controlled with a phone or tablet and is surprisingly close to a computer: it runs Linux, has high-speed Wi-Fi, and has a custom processor.

Opening It Up

Some of the screws from the robot

To open this robot up, 22 small Phillips head screws had to be removed. The plastic shell came apart in four pieces. To remove the circuit boards and motor assemblies, even more screws had to be removed.

Circuit Boards

One side of the circuit boards

It appears to be four or more layers and populated nearly exclusively with surface mount components on both sides of the board. The board has a handful of unpopulated surface mount footprints including a footprint for an RF shield. The board contains many small SMD components, numerous, and a few small BGA packages.

The other side of the circuit boards

The control board is nearly identical in construction to the Wi-Fi board. The two circuit boards are connected to each other with what appears to be a USB interface, based on silkscreen labels, wire colors, and the wire assembly, and power.

Custom Microprocessor

The custom processor

Controlling all of this is custom microprocessor. Not a lot of information could be found about this custom IC. It is in a BGA package and appears to be based off an ARM core. According to the manufacture's website, this processor runs Linux, but little else could be found about it.

Wi-Fi

The Wi-Fi transceiver

To control this toy, it creates its own Wi-Fi network. To accomplish this, it uses a Broadcom BCM43526 transceiver. This transceiver is in a quad-flat no-leads package. Originally announced in 2012, the BCM43526 transceiver supports 802.11AC with speeds up to 867 Mb/s and is intended for media intensive applications such as televisions, set-top boxes, and Blu-Ray players.

In this robot, the Wi-Fi connection streams VGA video and control commands. The transceiver interfaces over USB 2.0 to the processor.

The dual Wi-Fi front ends

In order to achieve the advertised 50-meter range, a pair of Skyworks SKY85803 Wi-Fi front ends are used. These front ends amplify, filter, transmit/receive switch, and diplex the RF into the transceiver. They are in a 4mm square 24-pin Land Grid Array (LGA) package. Depending on the protocol, band, and baud rate they can amplify up to +21dBm.

One of the Wi-Fi antennas

To send and receive the data, a pair of trace antennas on opposites edges of the PCB are used. They are isolated from the rest of the PCB with via fences.

USB

The micro USB port

For battery charging and saving images and videos from the robot, it contains a micro USB port. This is a combination through-hole and surface-mount USB port to ensure durability. A flash drive, sold separately, can be inserted into the USB port and the images and videos can be saved directly to it.

The USB hub

In order to interface with a flash drive and with the Wi-Fi transceiver, a USB hub controller is used. Microchip’s USB2513B is capable of supporting three downstream devices on a USB 2.0 interface. This USB hub also includes power management and ESD protection.

Camera

The VGA camera

To control the robot remotely a webcam and microphone provide sensory feedback? The camera on board is a VGA camera with a wide angle lens. The camera is in a small package, similar to what would be found in a cell phone. No markings are visible on the camera. Below the camera is a round magnetic microphone.

The ribbon cable from the camera

Connecting the camera to the circuit board is a two-layer, multi-conductor, flexible ribbon cable that is terminated in a 24 position connector. On one layer of the cable is shielding to protect several of the conductors that are more susceptible to interference.

The webcam driver

To interface the camera to the processor a camera driver is used. An Etron Tech eSP668 webcam driver is used. This driver features a parallel input from the camera and a USB 2.0 interface out. The driver is in a 48-QFN (6 x 6) package.

Sensor

The accelerometer and gyroscope

In order to position the robot for jumping an accelerator and gyroscope is packed inside of it. An InvenSense 6-Axis gyroscope and accelerometer is used. A MPU-6050 in an exposed pad package is intended for applications just like this, toys.

Motor Drivers

The H-bridge motor drivers

In order to drive the two drive motors there is a Texas Instruments DRV8333 dual H-Bridge in this robot. These H-Bridges are intended for use in applications with motors that draw 1.5A at 10.8V. These H-Bridges also feature over current and temperature protections and have the ability to attach an external current sense resistor to them.

Jumping Assembly

The jumping assembly

In order to make this Jumping Sumo Robot jump, it contains a pretty unique jumping mechanism. The mechanism has a small DC gear motor that rotates a cam. The cam causes a metal arm to retract compressing the two springs. A pin on the metal arm fits into a dip the cam wheel. When ‘fired’ the cam rotates past the dip where the cam drops off sharply the springs extend out causing the robot to jump.

The cam in the jumping assembly

The cam wheel rotates until a small microswitch closes, indicating to the processor that the robot is ready to jump. The jumping functionality is programmed not to work with a battery below 20%.

The microswitch

A small brushed DC motor with a gearhead is used to rotate the cam. This motor only has to go one direction and appears to have a higher gear ratio than the drive motors to generate more torque.

Drive Motor Assemblies

One of the drive motors

To drive the robot, two more small DC gear motors are used. These propel the robot at speeds up to 4.3 MPH. These motors drive wheels that are plastic with a soft closed cell foam tread. These motors appear to be derived from RC servos, frequently found in RC airplanes and cars. They contain a similar spline and diameter on their output shaft and contain an opening where the shaft a potentiometer is typically found in an RC servo.

The gears in the drive motors

To reduce the speed of the DC motor a series of plastic gears are used. There are three plastic gears with varying pitches. The output shaft is also the shaft of the final stage of reduction. The output shaft is supported on both sides with plastic bushings.

Battery

The 550mA lithium polymer battery

A lithium polymer battery that powers this robot is in a sealed plastic enclosure. The battery is a 3.7V 550mAh battery that connects to the robot with three gold-plated contacts. According to the label, the battery can be charged at 1A max and discharged at 8.25Amps continuously.

The three gold plated battery contacts

Conclusion

Pile of robot parts

For the current price, there is a lot of tech in this robot for the money. From researching the electronics in this article, it seems that Parrot uses a lot of the same technology in many of their products. Thanks for checking out this teardown! Stop by next week for another teardown!

No comments:

Post a Comment